I have had for a number of years quite a lot of

‘Eurotainers’- sturdy industrial plastic boxes, bought cheaply secondhand or

found at the local recycling centre. They prove really useful for storage, and

as they are a modest size, cope well when filled with heavy metal items. They

do, however have the disadvantage of not fitting efficiently on the Dexion

shelves I have and so they often end up stacked up, making it difficult to get

to items. I therefore decided to make a custom rack to fit them in.

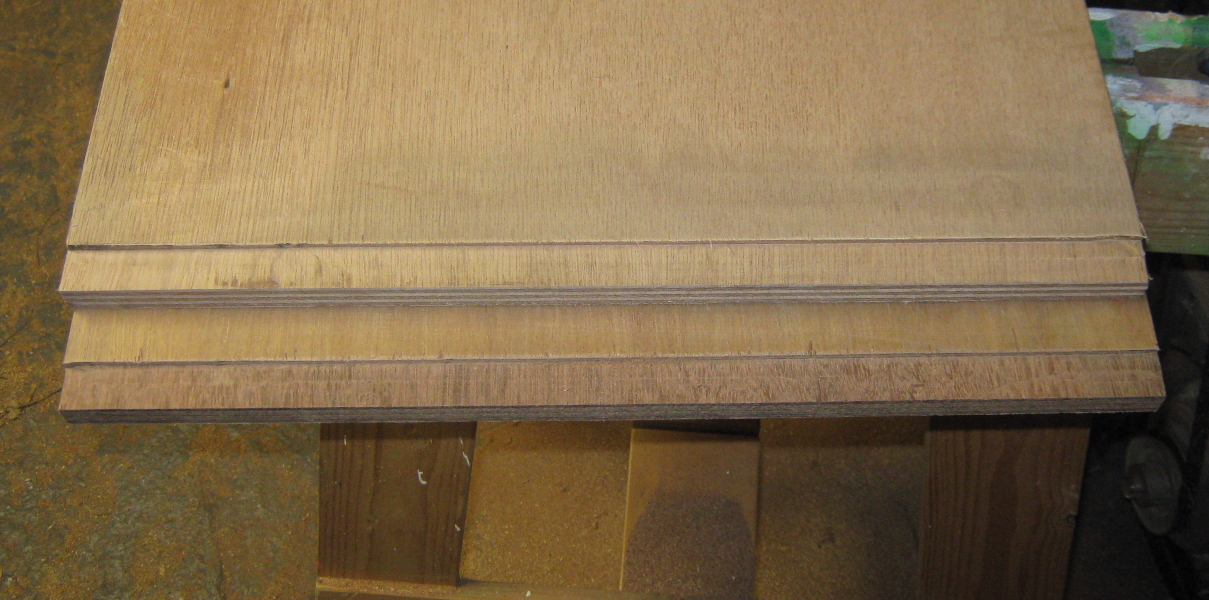

The build is a simple construction, mostly made of 18mm marine ply bought cheaply from Oxford Wood Recycling. The size was dictated largely by the wood available, whilst trying to keep it manageable.

Dividers and sides are let into dados & rebates, cut

with a router. Some 6mm ply is let into a rebate on the rear, and everything

glued and screwed (or nailed) up.

Edges are capped off with some strips cut from scrap Meranti

timber and glued and nailed to the front. The whole lot being finished with

some polyurethane varnish.

The unit sits on a small ply made with off cuts of ply and a

length of CLS, this time from Northampton Wood Recycling. This is painted in a

matt black.

Four adjustable feet were fitted into T-Nuts on the plinth

to allow levelling. The feet were adjusters recovered from a broken baby gate.

15 Eurotainers fit into vertical bays, each provided with

metal brackets that run along the stepped section on the base of the

containers. The brackets were cut from 1mm thick mild steel sheet, cut out on

the metal guillotine, holes punched in for screws with a Whitney type punch and

then folded using the Gabro folder. Screw holes are offset so screws clear each

other when screwed from both sides of the ply.

The Rack has been put in place in the workshop and already filled. I have a few smaller containers, so will probably now make another, smaller rack that sits on top to take these. Putting this in place also means a bit of a re-jig in the workshop.